Makinex were tasked with providing site power solutions for a 200MW solar farm construction site. The Solar farm has been built on more than 300 acres of grazed agricultural land. This project will power the equivalent of 44,000 homes and contributes to NSW’s ambition to increase its share of renewable energy to more than 60 percent by 2030.

The Challenge

The challenge was powering a 6mx3m office and lunchroom for site security that stood on its own at the road front of the 200MW solar farm construction site in Wellington. The site shed had to be powered 24/7. The location of the site shed being close to the road and residents meant that a quieter running option with fewer traffic movements was desired. Finally, the shed needed to be relocatable if required. A connection to grid electricity would provide silent power. However, it would be costly, involve a longer set-up time, and need further work if the customer relocated the shed. The customer determined that a diesel generator was a better option to power the shed as it was cost-effective and portable. However, it did not meet the brief of a quieter solution and seemed counterproductive to burn diesel fuel 24/7 on a renewable energy site.

The Solution

In response to this challenge, Makinex deployed the 20kVA Hybrid power system (HPS). The latest project is just the most recent example of our longstanding track record of providing innovative solutions that make inefficiencies extinct!

The HPS consists of roof-mounted solar panels, a battery bank to store energy, an integrated backup diesel generator, and an inverter to interface the different inputs.

The Outcome

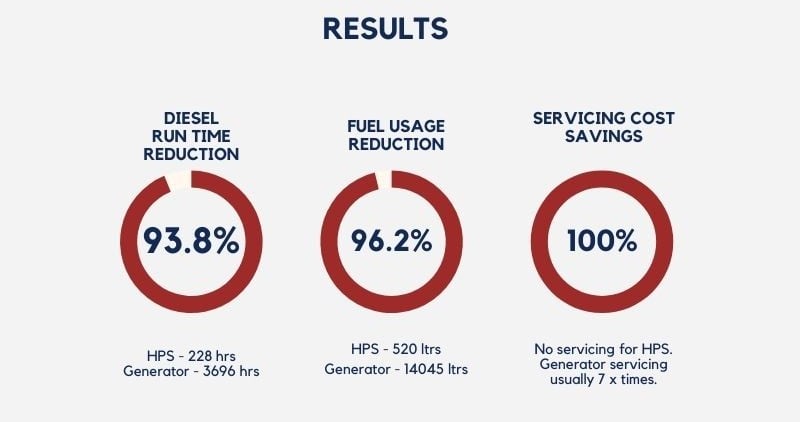

The HPS met the customer’s brief of being easy to deploy, relocate, and simple to install, like a portable generator. It was capable of running 24/7 with no disruptions to the residents as the diesel generator component of the HPS would only run every couple of days for a few hours and at designated times during the day. Over 22 weeks, the HPS 20 operated 24/7, with the diesel generator component running for only 7 % of the time.

The results were a 93% reduction in generator run time which directly relates to a significant decrease in fuel usage and servicing costs. This reduction in run time also reduced the traffic to the site, further reducing noise and improving site safety.

The added benefit of having reduced emissions on a renewable energy project was the cherry on top. Running the HPS as compared to a similar diesel generator for the same period reduced CO₂ Emissions by 20 tonnes.

“When the Makinex Team presented Kennards Hire with the opportunity to test the new hybrid generator, I instantly recognized this was an innovation that solved many challenges. The ability to run silently when on battery mode, environmental improvements with less emissions, and optimized fuel costs were immediately identified. Furthermore, the inclusion of telematics (IoT) provides my project teams to gain insights into numerous diagnostics (fuel levels, current draw, fault codes) at the click of a button, even when the unit is 100’s of kilometres away.”

Konrad Stempniak, General Manager from Kennards Group

Our customers have celebrated the impressive HPS design and implementation. Delivering portable, cleaner, quiet power and mitigating expenses involved with traditional grid or portable generator power, the HPS is everything it set out to be. Learn more about the product here.